Novitech and Xcel Energy present a 2nd paper on Circumferential Stress Corrosion Cracking at PPIM in Houston.

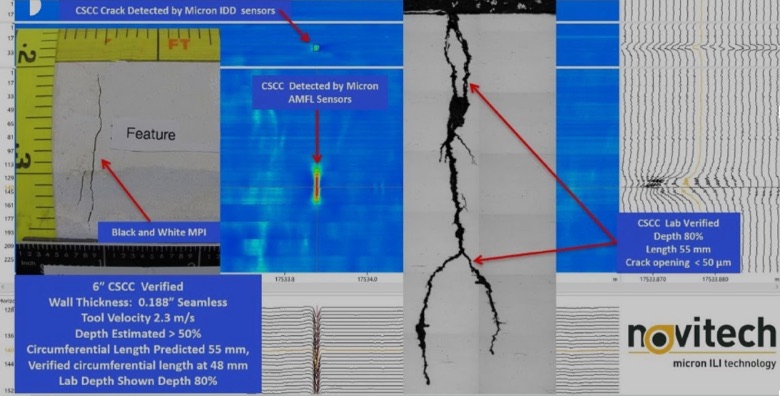

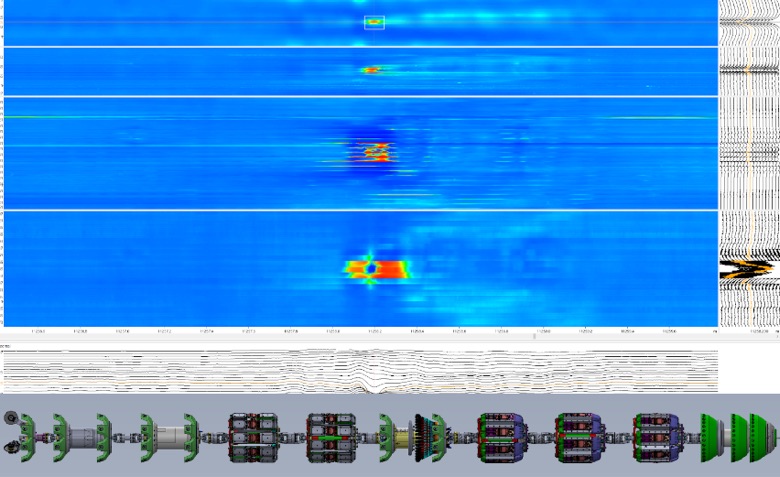

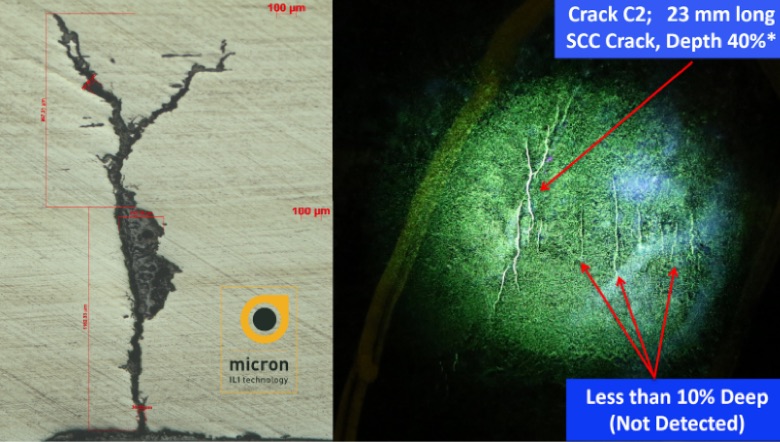

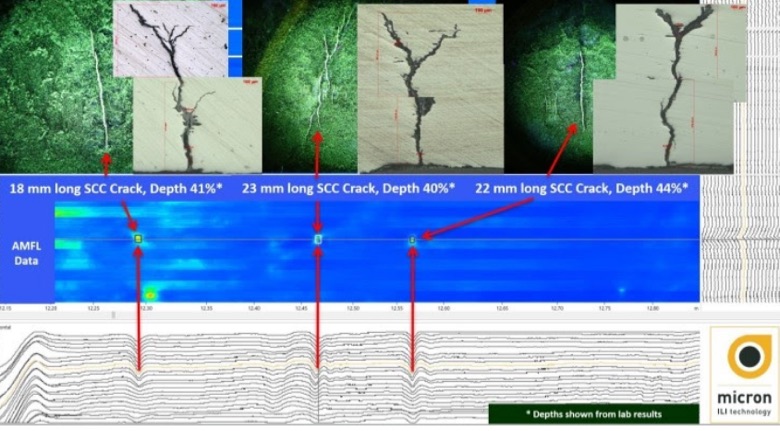

This paper was based 6” pipeline segment inspected for CSCC where numerous CSCC flaws were field and laboratory verified. For a copy of this paper please contact us at at info@novitechstage.com